News › Fraunhofer IOF · New optical coating system prevents fogging and unwanted reflections

Technology improves performance of LiDAR and other sensor and camera systems

Optics that do not fog up and hardly reflect at all – this will be possible in the future thanks to a new optical coating system. The technology developed by researchers at the Fraunhofer Institute for Applied Optics and Precision Engineering IOF is expected to help improve the performance of LiDAR systems and cameras in autonomous driving cars, for example. The research team is now presenting the new method with a paper in the journal »Applied Optics«.

»When you go from cold to a warm room, your glasses can fog up, severely limiting the vision of the person wearing them,« says Anne Gärtner. »The same can happen with sensors like the LiDAR systems in autonomous driving cars. Here, it is important that the surfaces remain highly transparent even when fogged, so that functionality is maintained.«

Gärtner and her team have therefore developed a novel optical coating system designed to prevent just that. In the journal Applied Optics, published by Optica Publishing Group, the researchers describe how they combined a polymer coating with porous silica nanostructures. In the process, the polymer coating prevents fogging while the nanostructures reduce reflections. Although the coatings described in the paper were developed specifically for LiDAR systems, the technology can be tailored for many different applications. LiDAR (light detection and ranging) refers to laser systems used for optical distance and speed measurement.

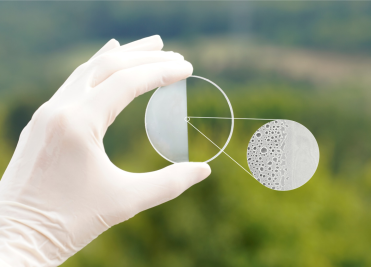

Fog-reducing and anti-reflective coating system to improve lidar systems, for example.

Optical coating system ensures clear vision

The novel coating system is based on the AR-plas2 technology developed at Fraunhofer IOF and was adapted to their requirements as part of the collaboration with Leica Geosystems AG from Heerbrugg, Switzerland. Leica Geosystems develops airborne LiDAR measurement systems used for terrain and urban mapping. Extreme temperature differences between the environment and the measurement system can cause fogging of the optical surfaces, which would impair functionality. To prevent this, Gärtner’s team then worked with Leica Geosystems to develop a solution that addressed both fogging and unwanted light reflections.

»We used a polymer that prevents fogging of an optical surface by acting as a water reservoir,« Gärtner explains. »However, differences in the refractive indices of the polymer material and the surrounding air lead to unwanted reflections and ghost light in the optical system. To prevent these reflections, we combined the anti-fogging layer with very small structures – up to 320 nm high – to achieve an anti-reflective effect with simultaneous water permeability.«

Multiple nanostructures on top of each other prevent reflections

AR-plas2 technology allows several nanostructures to be produced on top of each other. In this process, one nanostructure is etched into the anti-fog layer and then a second nanostructure is produced on top of it. With this technology, it is possible to adjust the refractive indices of the nanostructures and design the dual nanostructure to achieve very low reflection over a wide spectral range.

The researchers tested the antireflection and antifogging performance of their coating system using reflectance measurements with a spectrophotometer and fogging measurements. These were performed after holding the anti-reflective and anti-fog side of the optics over heated water. The laboratory tests showed that the multilayer system exhibits very low reflectance over a wide spectral range. This would not be possible with a single nanostructure. In addition, the nanostructures did not impair the effect of the underlying anti-fog layer. Due to the touch-sensitive nature of the surface, this form of layer system is particularly suitable for interior surfaces.

Application in quantum computers conceivable

AR-plas2 technology can be applied to almost all types of materials: polymers, but also glass or fluoride crystals. It is therefore widely applicable, for example for optics in lighting, automotive and consumer goods, but also for future technologies such as quantum computing. Here, researchers at Fraunhofer IOF are already developing systems made of optical layers and nanostructures for experiments to develop a quantum computer as part of the »Qzell« project.

»Optical systems are becoming increasingly complex, and with them the demands on image quality are also increasing,« says Gärtner. »Nanostructures can be used to achieve antireflection properties with impressive results that are often not feasible with conventional coatings. With the fundamental understanding we’ve gained in recent years, we’re confident that we can bring nanostructured coatings into many real-world applications.«

Original publication: A Gärtner, A. Sabbagh, U Schulz, F. Rickelt, A. Bingel, S. Wolleb, S. Schröder, A. Tünnermann: »Combined antifogging and antireflective double nanostructured coatings for LiDAR applications,« Applied Optics, 62, 7, pp. 112–116 (2023), DOI: 10.1364/AO.476974, URL:

https://opg.optica.org/ao/fulltext.cfm?uri=ao-62–7‑B112&id=525109

CONTACT

Anne Gärtner

Fraunhofer IOF

Albert-Einstein-Str. 7

07745 Jena

Phone +49 3641 807–522

Send e‑mail: ed.refohnuarf.foi@rentreaG.ennA